How a Membrane Switch Enhances User Experience in Modern Electronics

How a Membrane Switch Enhances User Experience in Modern Electronics

Blog Article

Understanding Membrane Switches Over: The Trick to Durable and Reliable Controls

Membrane layer switches over stand for a critical aspect of modern user interface style, blending capability with durability in different applications. As we explore the complexities of membrane layer buttons, it ends up being clear that their role in boosting control systems is both extensive and complicated, elevating questions about exactly how ideal to utilize their capabilities in future developments.

What Are Membrane Layer Buttons?

Membrane layer buttons are an innovative remedy in the realm of interface modern technology, integrating capability and style flawlessly. These tools function as a user interface in between customers and digital systems, incorporating several components right into a portable style. Typically constructed from versatile, thin layers of materials, membrane layer switches are designed to reply to touch, allowing customers to engage with machinery and digital devices effectively.

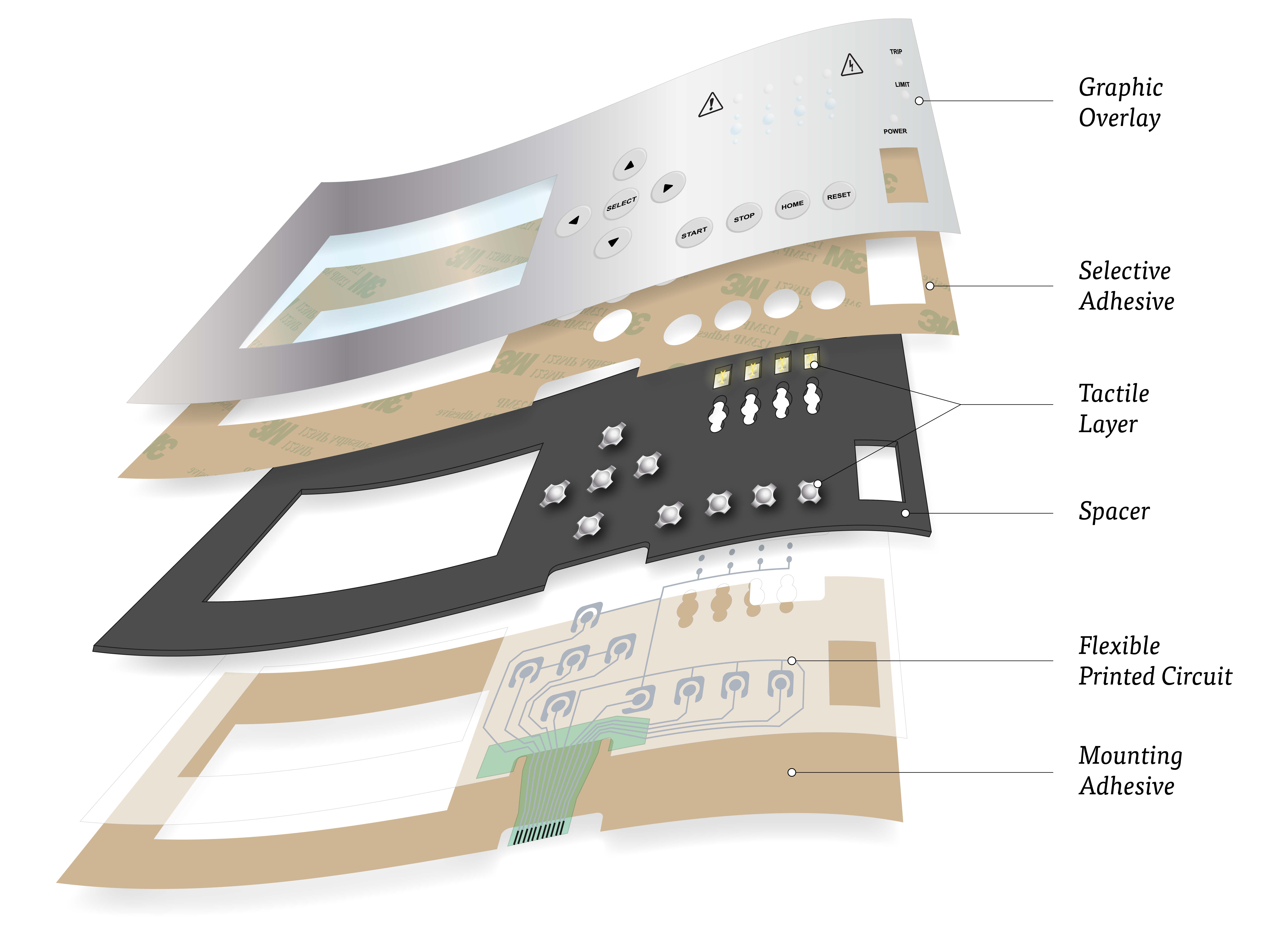

The key aspects of a membrane layer button include a published circuit layer, graphic overlay, and a spacer layer that protects against unexpected activation. The visuals overlay can be personalized to mirror brand identification or user preferences, improving aesthetic appeals while guaranteeing usability. Membrane layer switches are typically utilized in numerous applications, consisting of medical tools, consumer electronics, and commercial tools, owing to their toughness and resistance to environmental factors such as dampness and dirt.

One of the key benefits of membrane layer buttons is their capacity to endure wear and tear, making them ideal for high-traffic settings. In addition, they are light-weight and call for minimal space, permitting innovative layouts in product growth. Overall, membrane changes stand for a useful and efficient choice for modern-day digital user interfaces, weding technology with user-centric style principles.

Exactly How Membrane Layer Switches Job

The operation of membrane layer switches rest on a basic yet effective mechanism that converts customer input into electronic signals. These switches are composed of numerous layers, commonly including a visuals overlay, a spacer layer, and a circuit layer. When a customer presses the switch, the top layer warps, permitting a conductive aspect in the circuit layer to make contact with a matching conductive pad on the bottom of the visuals overlay. This contact shuts the circuit and sends an electronic signal to the gadget, suggesting that the button has actually been turned on.

The layout of membrane layer buttons can vary, yet they often integrate domes or tactile aspects to give comments to the individual, enhancing the total experience. The materials used in membrane switches, such as polyester or polycarbonate, add to their sturdiness and resistance to environmental elements, including dampness and dirt. The published circuits are typically encapsulated, which secures them from wear and tear over time.

Benefits of Membrane Layer Buttons

One of the primary advantages of membrane buttons is their adaptability in layout, allowing them to be tailored to meet details customer requirements and aesthetic demands. This adaptability prolongs to various markets, where different forms, sizes, and colors can be utilized to improve customer interaction and visual charm.

Additionally, membrane switches are understood for their toughness. Constructed from durable materials, they are immune to dust, moisture, and physical wear, which substantially prolongs their lifespan contrasted to conventional mechanical buttons. This sturdiness makes them particularly appropriate for high-traffic environments and applications requiring long life.

Moreover, membrane layer switches use a streamlined profile, leading to a thinner layout that can be incorporated right into numerous gadgets without including bulk. This function not just boosts the visual charm yet additionally adds to a more ergonomic item layout.

Applications of Membrane Layer Buttons

Straightforward and versatile, membrane layer buttons discover applications throughout you could try this out a wide variety of sectors, including medical tools, consumer electronic devices, and commercial devices. In the medical field, these switches are essential to gadgets such as diagnostic tools, person surveillance systems, and infusion pumps, where reliability and ease of cleaning are critical. Their ability to endure rough environments and maintain performance makes them perfect for such applications.

In consumer electronics, membrane layer buttons are utilized in items like microwaves, cleaning devices, and remotes - membrane switch. Their sleek style enables intuitive individual interfaces, improving the overall customer experience while providing toughness and resistance to use and tear

Commercial tools also takes advantage of membrane layer buttons, specifically in control panels for machinery and automation systems. These buttons offer security against dust and moisture, guaranteeing constant performance in challenging environments. In addition, their customizable functions enable producers to customize them to certain functional requirements, improving performance and capability.

Picking the Right Membrane Switch Over

When selecting a membrane switch, look at this now it is necessary to think about different elements that affect performance and suitability for certain applications. The key considerations include ecological conditions, responsive comments, resilience, and style specifications.

First, examine the operating setting; buttons subjected to dampness, chemicals, or severe temperatures call for particular products to ensure longevity and functionality. Next, evaluate the demand for tactile feedback. Relying on customer interaction, some applications might benefit from a responsive feedback to confirm activation, while others might like a non-tactile layout for visual factors.

Sturdiness is another vital factor; membrane switches ought to be developed to hold up against constant use, effects, and abrasion. Guarantee the selected switch can sustain the expected lifecycle, specifically in high-usage circumstances.

Conclusion

In final thought, membrane layer changes serve as essential parts in the layout of resilient and reliable control systems across numerous sectors. The versatility of membrane layer switches allows for tailored options that satisfy particular functional needs, enhancing their significance in modern technology.

Membrane switches stand for an important aspect of contemporary interface layout, blending functionality with durability in different applications.Membrane layer switches are a sophisticated service in the realm of user interface modern technology, incorporating functionality and design seamlessly. Generally constructed from adaptable, thin layers of materials, membrane layer buttons are designed to react to touch, allowing individuals to engage with equipment and electronic tools effectively.

The style of membrane blog buttons can differ, yet they often incorporate domes or responsive elements to offer comments to the user, improving the general experience.In verdict, membrane layer switches over serve as essential components in the style of durable and reputable control systems throughout various markets.

Report this page